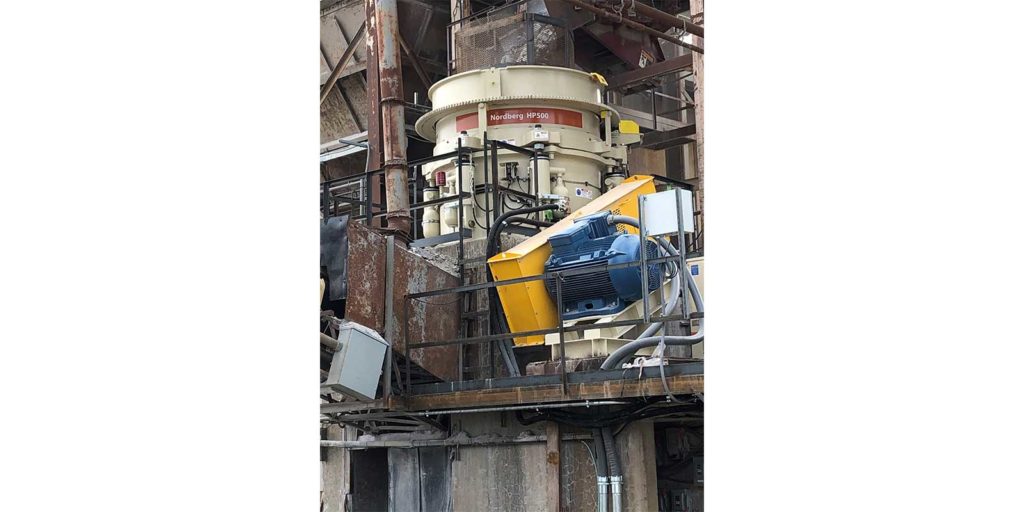

Your cone crusher is a vital component of your operations, and like any piece of machinery, it may encounter issues and setbacks during its lifespan. Being familiar with the most common problems that may arise, and their potential solutions, is crucial to keeping your equipment and cone crusher parts functioning at optimal performance.

Here are some challenges you may face with your cone crusher.

High Oil Temperature

If the oil temperature in your cone crusher is too high, it could be caused by poor-quality oil, insufficient oil, damaged bearings, high ambient temperature, low cooling water pressure, or a clogged cooler. To address this issue, you should change the oil or refuel, replace damaged bearings, supply cooling water or increase water pressure, and clean the cooler.

Oil Temperature and Pressure Rise

Oil Temperature and Pressure Rise

A clogged tubing or oil groove or a faulty safety valve can cause oil temperature and pressure to rise in your cone crusher. Stop the machine, check and repair the clogged tubing or oil groove, and replace the faulty safety valve.

Low Oil Pressure After Oil Pump Startup

Low oil pressure can occur if the oil temperature is too low, if there are blocked pipes, or if the oil pump isn’t working correctly. When this happens, you should heat the oil to increase its temperature, repair or replace blocked pipes, and fix or replace the oil pump.

Oil Containing Fine Mud and Impurities

The failure of the sealing dustproof device or a water shortage caused by blocked or leaking water pipes can lead to the oil being contaminated with fine mud and impurities. To fix this problem, seal or clean the dustproof device after shutting the machine down and replace the contaminated oil with new oil.

Presence of Water in the Oil

Some reasons there may be water in your cone crusher’s oil include water entering the lean oil station, a leaking cooler, and higher water pressure than oil pressure. Alternatively, the machine might be getting too much water, or you have a blocked return pipe.

Cleaning the oil tank and replacing the oil is the first step. You may also have to repair or replace the cooler if it’s leaking, reduce the water pressure or adjust the water supply, clean the return pipe, and replace the oil with new oil.

Excessive Vibration of the Cone Crusher

If your cone crusher is vibrating far more than it should, you might have loose fastening bolts in the base, broken or worn parts, or poor lubrication. Alternatively, difficult-to-break materials may have been fed into the machine and caused a blockage.

To solve the problem, tighten the bolts, control the type and amount of feed material, and stop the machine to check and replace any damaged cone crusher parts. Additionally, inspect and maintain the oil pumps and pipelines to ensure adequate lubrication.

High Rotation Speed of the Crushing Cone

If the crushing cone is rotating too fast, you might have an oil shortage or dust in the oil between the spindle and bushing. Other potential causes include insufficient clearance of the tapered bushing, bowl-bearing bush wear, or manufacturing issues.

To address this problem, overhaul or replace the bushings and spindles, find the cause of the oil shortage and fix it, adjust the bushing clearance, and rescrape the contact surfaces.

Sudden Acceleration of the Moving Cone

If you notice the sudden acceleration of the moving cone in your cone crusher, it may be due to the sinking of the moving cone, damage to the spherical thrust bearing, or the conical bushing upstream of the spindle may cause insufficient clearance with the spindle. To fix this issue, you should adjust the gap.

Nonuniform Rotation of the Transmission Shaft

If the transmission shaft in your cone crusher isn’t rotating uniformly, you might have severe wear or damage to the gears, the connection keys might be damaged, or the spindle might be broken. To solve this problem, replace the gears, ensure the meshing clearance meets requirements, change the connection keys, replace the spindle, and improve the screening process.

Splitting Sounds During Operation

If your cone crusher makes splitting sounds, it may be because of a loose lining plate or a moving or fixed cone lining plate that isn’t the proper round shape. This can cause impact and damage to the equipment. Stop the machine, check if the screw is tight enough, and determine if the zinc layer has fallen off.

Coupling Rotation Without Crusher Movement

If your cone crusher’s coupling rotates but the crusher doesn’t move, the issue may be with the transmission coupling, gear key break, or spindle breakage. Your best option is to disassemble the machine to locate and replace the faulty cone crusher parts.

Strong Knocking in the Drive Shaft

A loud knock in the drive shaft of your cone crusher may indicate poorly installed bevel gears, poor meshing, excessive clearance, a too large axial clearance of the transmission shaft, or gear damage. You’ll need to correct the meshing clearance or replace the gear.

Supporting Ring Bounces

If the supporting ring bounces in your cone crusher, you might have nonfragments getting into the crushing chamber, which could lead to the main shaft breaking. To prevent this issue, improve your screening process to reduce the likelihood of iron and other metals being fed into the crusher. You may also want to consider installing an iron remover.

If the supporting ring bounces in your cone crusher, you might have nonfragments getting into the crushing chamber, which could lead to the main shaft breaking. To prevent this issue, improve your screening process to reduce the likelihood of iron and other metals being fed into the crusher. You may also want to consider installing an iron remover.

Increased Size of Material Output

If you find that the output size of the material has increased seemingly at random, you’ll need to check the liner as it may have severe wear. Adjust and reduce the size of the outlet and replace the lining plate.

Keep Your Cone Crusher Operating at Peak Performance With Mellott

Cone crushers may be heavy-duty equipment meant to operate under challenging conditions, but they are still susceptible to various problems. By understanding the common issues that can arise with cone crushers and working with an experienced equipment provider like Mellott, you can ensure that your equipment functions effectively and efficiently, maximizing your productivity and profitability.

Whether you need routine maintenance, high-quality cone crusher parts, or new equipment, Mellott has the experience, knowledge, and resources to help you get the most out of your cone crusher. Contact us today at 855-554-1606 or online to learn more about how we can help you.