Contract Crushing, or as some people call it “Custom Crushing”, is a service that has solved many problems for aggregate producers over the past multiple decades. Whether it is opening a greenfield site, gaining added salable inventory through supplemental crushing, recycling asphalt or concrete, or the myriad of other needs, Mellott has implemented many solutions for customers utilizing Contract Crushing. In fact, Contract Crushing has been the heart and soul of our organization since the 1970s. We’ve partnered with small family-owned operations, we’ve helped build aggregate producer empires, and everything in between. Mellott’s contract crushing division has reached an unparalleled level of excellence in providing solutions to our producer customers in areas such as:

What Is Wash Equipment?

Wash equipment is a term used for a variety of machines that are used to clean aggregate mixture. This can include scrubbers, washers, and dryers. The main benefit of using wash equipment is that it can help to remove any debris or dirt from the aggregate mixture. This can help to improve the quality of the final product.

Additionally, wash equipment can also help to reduce the amount of moisture in the aggregate mixture. This can be important for products that need to be dried after production. Additionally, wash equipment can also help reduce the amount of dust that is created during the manufacturing process. This can improve worker safety and keep the surrounding environment clean.

Types Of Wash Equipment

There are a variety of different options when it comes to choosing washing equipment:

Dewatering Screens

Dewatering screens are machines used in many industries to separate liquids from solids. Dewatering screens are made of a wire cloth or mesh, and they remove liquid particles from aggregate mixtures such as sand, coal, iron ore and more. This is an essential step in water treatment and wastewater management.

Dewatering screens are an important part of wash equipment. They help remove water from the aggregate mixture, which makes it easier to transport and store. Dewatering screens also improve the quality of the aggregate mixture by removing any impurities that may be present.

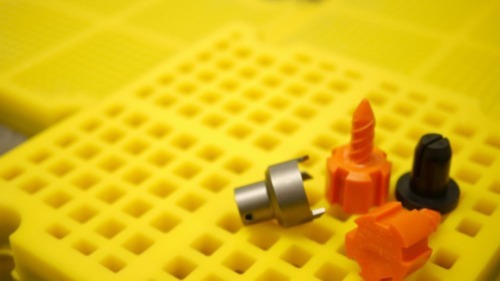

Screws/Log Washers

Aggregate mixtures sometimes need to be processed further in order to remove impurities such as plastics and clay. Log washers and screw washers can provide an extra layer of processing to help achieve the desired specifications.

Screws and log washers are two types of wash equipment that are used to clean the aggregate mixture. Screws are a type of rotary wash equipment that uses a screw conveyor to move the aggregate mixture through a washing system. Log washers are a type of wash equipment that uses a rotating drum to wash the aggregate mixture.

Tanks

Aggregate production tank systems are an important part of keeping equipment clean, running efficiently and an essential part of aggregate production. They help keep equipment clean and free of debris, which can have a huge impact on the long-term performance and lifespan of your aggregate production equipment. Additionally, tank wash systems protect the environment by preventing pollutants from entering waterways. They are typically used to clean trucks, equipment and tanks used in aggregate production projects.

In the aggregate mixture process, wash equipment is used to clean and sort rocks and gravel. This is important for creating the right mixture that meets your project’s specifications. This equipment includes tanks of various sizes and shapes that use different methods to clean the rocks.

UFR's

Ultra Fines Recovery systems (UFRs) are used to recycle materials from the tailing stream of processing plants and dewatering systems. These systems are effective and can help to provide a variety of benefits to aggregate production processes. Ultra Fines Recovery systems, or UFRs, capture small particles released during the production of aggregates. They are an important part of the aggregate production process because they help ensure that the final product is of the highest quality by separating small particles from larger ones using screens.

Reach Out To Mellott For Aggregate Washing Equipment Rentals

The process of cleaning and purifying an aggregate mixture according to the specific needs of your project is an important step in many types of projects. With a high-level, well-functioning wash machine, you can ensure that your aggregate mixtures are free of the substances and liquids that need to be removed from the mixtures you need to produce.

At Mellott, we offer a wide selection of superior wash equipment that has been expertly maintained. Renting our wash equipment can help you meet the unique specifications of your project with ease without the added burden of purchasing new equipment or spending on maintenance. Reach out to our team of experts today at (855) 554-1606.

"*" indicates required fields