Contract Crushing, or as some people call it “Custom Crushing”, is a service that has solved many problems for aggregate producers over the past multiple decades. Whether it is opening a greenfield site, gaining added salable inventory through supplemental crushing, recycling asphalt or concrete, or the myriad of other needs, Mellott has implemented many solutions for customers utilizing Contract Crushing. In fact, Contract Crushing has been the heart and soul of our organization since the 1970s. We’ve partnered with small family-owned operations, we’ve helped build aggregate producer empires, and everything in between. Mellott’s contract crushing division has reached an unparalleled level of excellence in providing solutions to our producer customers in areas such as:

Proven Equipment Maintenance & Repair Services

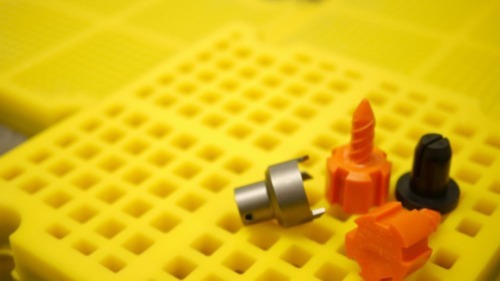

Our team is capable of fully repairing and maintaining aggregate equipment that includes crushers, screens, conveyors, tanks, and more. Our team has repaired and rebuilt nearly 3000 crushers and collectively, we have over 30 years of experience in the aggregate production field.

These pieces of equipment experience significant wear and tear during usage in most projects, which makes maintenance essential to improve longevity. Without proper maintenance and repair, these machines can break down and significantly slow down production.

It is important to have a reliable maintenance and repair service to keep your aggregate equipment running smoothly. Our maintenance and repair service consists of a team of experienced technicians who can quickly diagnose and fix any problems you are experiencing with your equipment. They will also be able to provide regular maintenance services to help prevent any problems from occurring in the first place.

Benefits Of Mellott Maintenance Services

When it comes to ensuring your aggregate equipment is running at its best, it’s important to work with an expert maintenance team. By doing so, you can enjoy several benefits, including:

- Reduced downtime: Expert maintenance teams know how to quickly and effectively diagnose and fix any problems with your equipment. This means less time spent waiting for repairs, and more time getting your business back up and running.

- Improved performance: Poorly maintained equipment can lead to decreased performance and efficiency. By working with an expert team, you can ensure that your equipment is always running at its best.

- Reduced costs: Badly performing or malfunctioning aggregate equipment can result in increased costs due to wasted time and materials. An expert maintenance team can help you avoid these costly issues.

Expertly Guided Equipment Maintenance With Mellott

Our team understands how important it is to keep up with the maintenance and repairs of your aggregate production machinery. Operational downtime can be very costly, and we are here to help you stay on track.

Main features of our industry-leading services include:

- Exclusive OEM-Authorized Crusher Repair Center with rights to intellectual property.

- 10,000 cubic foot Stress Relief Gas Oven—required for proper weld and Machining repair.

- Over 16,000 parts numbers active

- Field and shop inspections to ensure high standards

- Specialization in large machinery such as jaw, gyratory, and cone crushers

Trust The Experts At Mellott With Your Maintenance & Repair Needs

Our team has a proven track record of success and can help your operation continue to run smoothie despite any operational difficulties you may be experiencing.

Our services are guided by a team of experts and we always strive to offer personalized guidance and recommendations on your unique situation. For more information on how we can help you with your maintenance and repair needs in the aggregate production industry, reach out to our team of experts today at (855) 554-1606 or fill out our form below.