Home / Equipment

Mellott has the experience and knowledge for a large variety of different makes and models of rock crushers, so we are the right choice to get you with the right machine for your operation!

Contact us today or explore our equipment offerings below to request a quote!

Mobile Plants

Track Mobile Plants

Tracked plants offer the mobility that large operations demand from their rock crushing machinery without compromising on uptime costs. Ideal for jobs where rock crushing has to occur over a long stretch of ground tracked plants can be deployed quickly without leaving a large footprint.

Operating a tracked plant is relatively simpler than other rock crushing systems. They require minimal experience to operate and in many cases, they eliminate the need for conveyor transfers.

Wheeled Mobile Plants

Wheeled plants are the answer when a rock crushing site needs the capabilities of a fixed crushing operation with the mobility benefits of having transportable equipment. A wheeled plant operation may require conveyors or haul trucks to move materials to and from the screens. But the power lies in the ability to move operations between multiple locations on site.

Most wheeled plants are operational in move environments regardless of area or infrastructure.

Rock Crushers

Rock crushers help to prepare the aggregate materials that are needed for most construction projects. These essential pieces of machinery do the heavy lifting when materials need to be broken down into aggregate mixtures for use as foundation and fillers. The type of rock crusher equipment that you may need will vary based on the needs of your project and the materials you plan to work with. We have a wide selection of different types of rock crushers that can help you get the job done right.

We sell and rent the following types of rock crushing equipment:

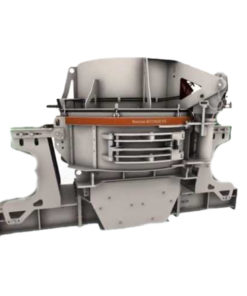

Gyratory Crushers

Gyratory crushers are a type of rock crusher that use a spinning cone to break rocks apart. They are often used in mining and quarrying operations, as they can handle large chunks of rock. Gyratory crushers can be divided into two categories: primary and secondary.

A primary gyratory crusher is the first step in breaking down rock, while a secondary gyratory crusher is used to further reduce the size of rock particles.

Cone Crushers

Cone crushers are a type of rock crusher that uses a curved cone-shaped surface to break down rock.

The benefits of using cone crushers include that they can handle large rocks, they can produce a smaller particle size, and they are adaptable to different types of rock.

Jaw Crushers

Jaw rock crushers are designed to crush rocks and boulders into smaller pieces.

This type of rock crusher is ideal for quarries and construction sites, as it can handle large rocks and boulders easily. Additionally, jaw rock crushers are very efficient and can produce high-quality aggregate quickly.

HSI/VSI Crushers

An impact crusher is a machine that uses kinetic energy to crush rocks. It works by smashing rocks against each other, which breaks them down into smaller pieces. This type of crusher is often used in quarries and recycling operations.

One of the benefits of using an impact crusher is that it can produce a very fine rock powder. This can be helpful in certain applications, such as in manufacturing or construction. Another benefit is that an impact crusher can handle a wide variety of rock types, including harder materials that might cause problems for other types of crushers.

Rock Screens

Horizontal Screens

Horizontal screens are highly effective as the final screen of an operation as rock and material are filtered through longer, more thorough vibrations. This allows for smaller rocks to be processed into finer materials using smaller grade holes.

You want to make sure your horizontal screens are robust enough to withstand the immense vibration and wear from the more thorough filter. Machines also need enough horsepower to move the screens with enough force to push the rock and material through.

Inclined Screens

Inclined screens work at high capacities to quickly and efficiently process large amounts of materials. These screens are mostly used in the processing stage of material.

Since inclined screens are working with gravity to push rock and material through, they are built with more cost-effective designs and materials. They will also work with lighter engines.

Wash Equipment

Dewatering Screens

Dewatering screens produce fine aggregate materials with low moisture content. When working with natural or manufactured aggregates it’s essential to remove deleterious materials for the most product possible.

Screws & Log Washers

Screws and log washers are parts of rotary wash equipment that utilize screws to push rock and materials onto a conveyor and through the rest of the washing system. A log washer is a rotating drum that swishes rock and material around and washes the aggregate mixture.

Tanks

Materials are fed into washing tanks and a series of filtering systems that separate aggregate by size and gravity. Some tanks will have a system of troughs to blend materials like sand and create products or host excess.

UFRs

Ultra Fines Recovery Systems (UFRs) utilize a series of screens to collect loose small particles during the aggregate production process for the highest quality product. Rock crushing operations may see reduced wear to other processing equipment while minimizing energy use.

Other Equipment

Conveyors

Conveyors help move aggregate materials between locations and are the backbone of an aggregate production system. Operation managers can increase efficiency and reduce the need for manual labor with conveyors that scale with production.

We offer belt conveyors, screw conveyors, and pneumatic conveyors of various grades and specialties to help your production.

Feeders

Feeders provide your aggregate production with a consistent flow of materials to crushers so they’re constantly operating a full capacity. Aggregate production companies can prevent interruptions from clogs or other problems.

There are a few different types of feeders used in aggregate production: the grizzly feeder, pan feeder, and belt feeder. Each feeder will help transfer materials with their unique specialties for certain materials and production volumes.

Most wheeled plants are operational in move environments regardless of area or infrastructure.

Rock Breakers

Rock breakers help turn large rocks into smaller, workable rocks, gravel, or dust. They’re designed for the primary stage of rock crushing and process brittle materials like rock, ore, slag, and refractories.

There are two main factors to consider when choosing a rock breaker: the size of the material and the volume of material to be processed.