Rock breakers are a staple for demolishing large layers of hard rock and materials. Their compact design allows for quick and efficient rock breaking against challenging surface areas. Rock breakers have several hammer options for the most specialized work and perform with speed and reliability.

Depending on your unique need and the demands of your next project, you will need to be matched with the right type of rock breaker equipment. Different types of rock breakers offer their unique set of benefits and drawbacks, making selecting the proper type of equipment essential. Our team of experts can help you find the rock breaker equipment that will help you get your next project completed on budget and efficiently.

What Is A Rock Breaker?

A rock breaker, or “hammer”, is heavy machinery where a piston hammer pummels the surface of hard materials like concrete, asphalt, or stone. They are designed for the primary stage of the crushing of hard, brittle materials such as rock, ore, slag, and refractories. It is a common tool for mining and construction projects needing a fine aggregate mixture.

Hydraulic rock breakers are typically used as the first step in the reduction process because they can handle larger rocks than most other types of machines and break down tough to work with materials effortlessly. They have a compact design making them ideal for busy project sites and tight urban areas. The piston is aimed at the center of a massive rock and a series of changing oil pressures moves the hammer upward and downward to break materials.

Rock breakers have been used in mining and are most commonly used to break large pieces of concrete or settled rock materials for building.

How To Choose The Right Rock Breaker

When selecting a hydraulic rock breaker, it is important to consider the type of material to be crushed, the size of the feed and product, and the type of crusher.

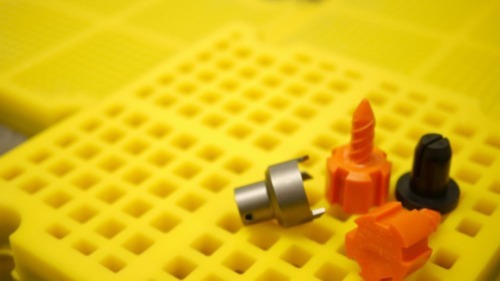

It is important to choose a rock breaker that is large enough to handle the amount of material you will be processing. There are two main categories for the hammer – chisel hammer and blunt hammer – with further specializations to get a job done efficiently. Some rock breakers will also have a spade attachment to move crushed materials off the work site.

Available Rock Breakers

Contact The Rock Breaker Experts At Mellott

If you need to find a rock breaker that fits the needs of your next project, our team of rock breaker experts can help pair you with the equipment that perfectly suits your needs. At Mellott, we offer hydraulic rock breakers for rent and sale so you can make the investment that makes sense for your organizational requirements. For more information, reach out to our team today at (855) 554-1606.

"*" indicates required fields