What Is A Cone Crusher?

A cone crusher is a heavy-duty machine that reduces rock and other raw materials by compressing them between a moving cone and a stationary outer shell. This process breaks down large, coarse materials into smaller, more consistent sizes ideal for aggregate production.

Cone crushers play a vital role across many industries, including:

-

Mining

-

Rock quarrying

-

Mineral processing

-

Recycling

-

Sand and gravel production

-

Building materials manufacturing

Types Of Cone Crushers

There are two types of cone crushers: standard cone crushers and hydraulic cone crushers. Standard cone crushers are the most common type of cone crusher. They use a movable cone to break down the rocks. Hydraulic cone crushers are a newer type of cone crusher that uses hydraulics to crush the rocks.

Cone crushers are a great asset for any project that needs to break down rock and other materials into a finer aggregate mixture of materials. Cone crushers are a great option for a variety of different materials due to their powerful capabilities and their rugged durability. They can be used for different sizes of rocks and types of materials, making them a good choice for multiple types of projects. Additionally, cone crushers are very versatile and can be used in a variety of applications.

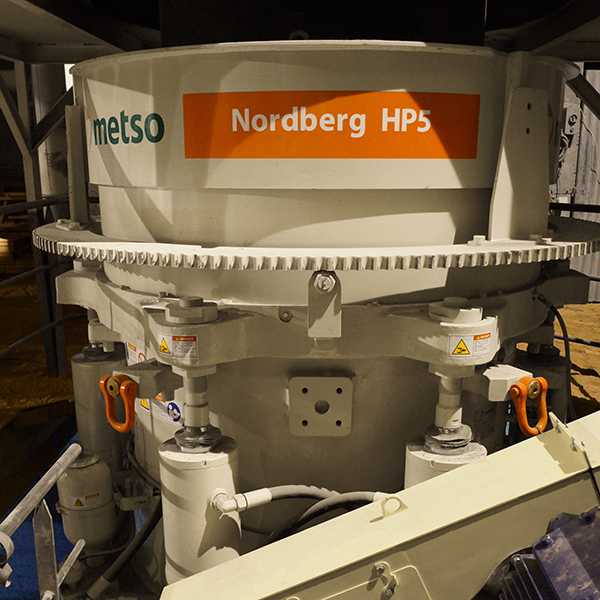

HP Series Cones

GP Series Cones

Other Cones

How Cone Crushers Work

The material is fed into the top of a cone crusher, which then crushes it between its mantle and concaves. This happens in the crushing chamber. As the feed moves down towards the drive end of the cone crusher, its size decreases, and ever smaller pieces move towards the drive end of the crusher. After passing through the crusher, the product is now at a much-reduced size and is discharged through an opening in the bottom shell.

Cone crushers are quite a simple machine. Though they appear intimidating at first, once you know the different parts of the device, it becomes much easier to understand how they work: The Feed Opening and Concave are two parts that help move rock through the machine; The Mantle is a piece of metal between the opening and concave that helps compress rock; The OSS & CSS–or Overhead Safety System–is an electronic sensor that detects when something is wrong with the cone crusher; The Motor turns a shaft that moves all of these parts together; And finally, Feeders funnel rock from one part of the machine to another.

Advantages Of Cone Crushers

Cone crushers offer many advantages over other types of rock crushers.

Efficiency

First, cone crushers are very efficient at crushing materials. They can handle large chunks of rock and produce a very fine product. This will help to make projects run more smoothly and be more capable of creating aggregate more quickly.

Durability

Additionally, cone crushers are durable and require little maintenance. This makes them a cost-effective option for many businesses. They have a long lifespan and require very little maintenance. This makes them a good option for businesses that need a reliable rock crusher for rent, as you can rest assured that it will function at a high level.

Flexibility

Cone crushers are strong enough to handle multiple types of use cases. Their efficient design and powerful capabilities make them able to handle multiple types of projects.

Tips For Getting The Most Out Of Your Cone Crusher

While careful adjustments are critical to achieving optimal efficiency, there are also some simple things you can do to help your crusher perform at an optimal level.

Maintaining a maximum level of performance requires a complete understanding of the application parameters, design limitations of the crushing machine and processing circuitry needed to support that machine. To get the most out of your crusher, make sure to follow these simple steps:

Understand Limitations

To maximize throughput, every crusher cavity has a volume limit that must be adhered to. If you exceed this volume, it will have implications for your final product size and it will also reduce the productivity of your machine. If your feed material is overflowing out of the top of the feed opening, you’ve exceeded your volume limit. The cone crusher can lead to premature wear and burn out.

Keep Your Closed Side Settings Consistent

To achieve consistent results, it is important to use consistent Closed Side Settings (CSS). If these settings are changed, it can affect the production process and cause a final product that is larger or less uniform than intended. Additionally, an oversized product can cause other issues within the circuit flow.

Steady Feed Flow

The way material is fed into the crusher has a notable effect on the shape and quality of the final product. If you keep a consistent feed level throughout a shift, you’ll produce more efficiently, improve quality and prevent downtime.