Save yourself time, money, and headaches by following proper greasing guidelines.

If a little bit of something is good, it might be tempting to think that “more is better”.

Grease is one of those things where a little dab makes things run smoother and quieter—

but too much can spell disaster!

Too much of a good thing isn’t always a good thing

Over greasing can lead to high operating temperatures, collapsed seals and in the case of

electric motors, energy loss and failure.

Stop the over greasing madness

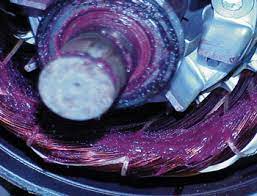

Too much grease in bearing cavity will cause the rotating bearing elements to begin churning the grease. This builds heat that leads to cooking the grease into a crusty build-up that interferes with proper lubrication of the bearing.

Don’t let over greasing ruin your equipment

Grease guns can produce pressures of up to 15,000psi and can easily cause lip seals to

rupture which allows dirt and water to be drawn into the bearing housing.

Don’t let too much grease be your equipment’s downfall

Over greasing an electric motor tends to coat the windings and insulation which prevents heat from escaping and leads to premature motor failure.

Some tips to control over greasing:

Discontinue greasing when you feel abnormal back pressure;

Always make sure exhaust ports are cleaned out from any debris, or old, hard crust

that could be blocking the passageway;

Consider getting grease guns with pressure gauges, shut-off grease fittings or relief type

vent plugs;

Slowly pump grease into bearings every few seconds. Using a quick-lever could cause

seal damage and not allow the grease to distribute evenly throughout the bearing

correctly;

Find and follow equipment manufacturers’ recommendations for lubrication practices.