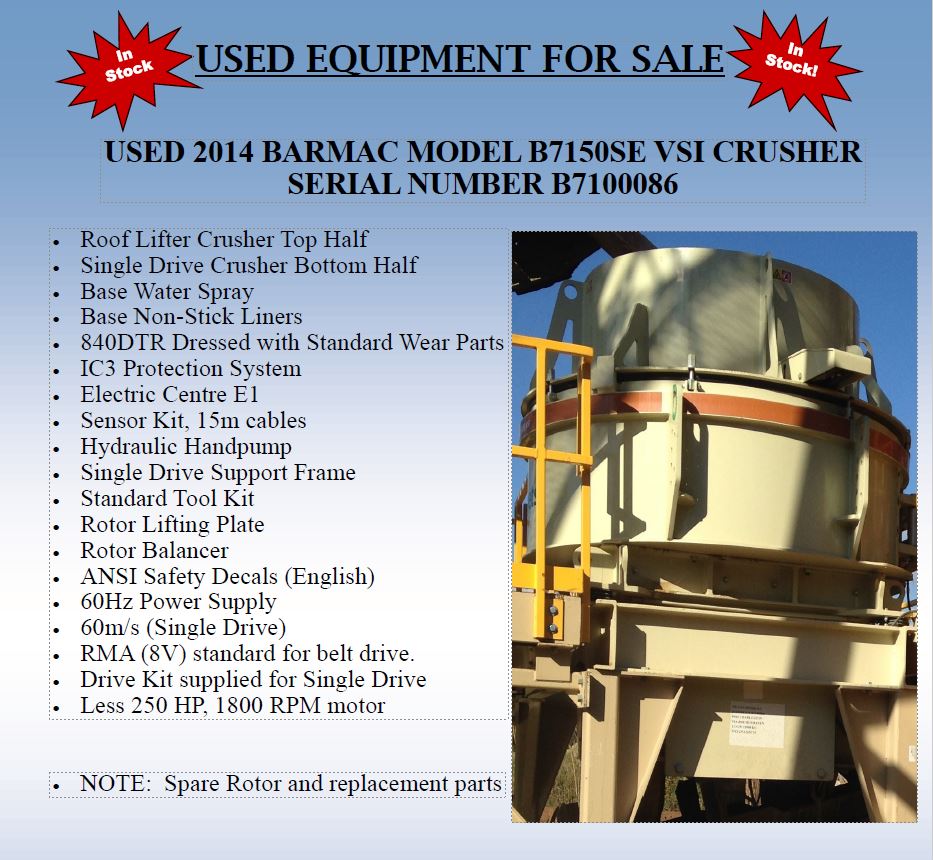

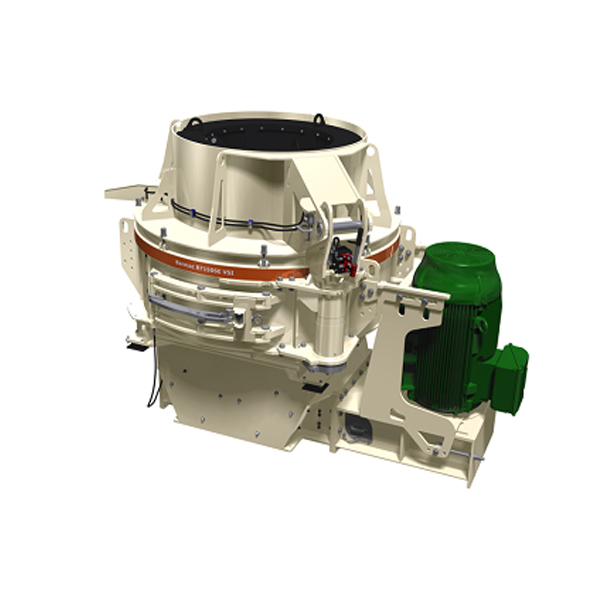

Barmac Series VSI Crushers

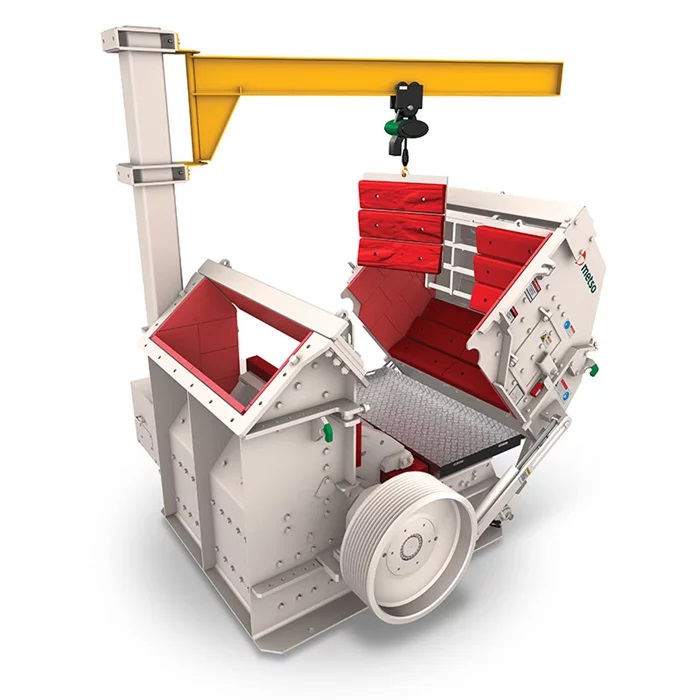

NP Series HSI Crushers

What Are HSI & VSI Rock Crushers?

HSI and VSI rock crushers are both valuable tools for crushing rocks. HSI rock crushers use high-speed impact to break down materials, while VSI rock crushers use a spinning action to break down materials. Both of these methods are effective at breaking down rocks and can be used for a variety of purposes.

One of the main benefits of HSI and VSI Rock Crushers is that they can be used to process a variety of materials. HSI Rock Crushers are effective at breaking down concrete and asphalt, while VSI Rock Crushers can be used to process sand, gravel, and other materials. This makes them versatile tools that can be used for a variety of applications.

Another benefit of HSI and VSI Rock Crushers is that they are very efficient machines. HSI Rock Crushers can break down material at a rate of up to 800 tons per hour, while VSI Rock Crushers can break down material at a rate of up to 2,000 tons per hour. This makes them fast and efficient machines that can get the job done quickly in the right circumstances.

HSI And VSI Rock Crusher Use Cases

HSI and VSI rock crushers are typically used in different ways, depending on the project. HSI crushers are generally used for softer materials, such as asphalt or concrete. VSI crushers are often used for harder materials, such as granite or limestone.

HSI rock crushers are typically used in projects where smaller, more accurate particles are needed. They can be used for a variety of tasks, such as:

- Demolition: HSI rock crushers can be used to demolish buildings and other structures.

- Recycling: HSI rock crushers can be used to recycle materials such as concrete, asphalt, and brick.

- Road Construction: HSI rock crushers can be used to create road base material.