Selecting the correct screen for your quarry can be challenging, but getting it right makes the payback well worth it. Per Russ Coverdale, Application Manager for Mellott, “Strategic sampling throughout a processing plant is an effective solution to determine processing efficiency during production. This can be accomplished by taking conveyor belt cuts and performing a gradation analysis while recording the tons per hour on the conveyor. Prime locations for this type of sampling would be screen feed conveyors, oversize return conveyors, crusher feed & discharge conveyors as well as any final product stackers. This simple exercise can quickly reveal screening in-efficiencies or poor crusher performance which when corrected can improve overall plant performance.” Your screen is your cash register, so selecting the right one will make your bottom-line rock!

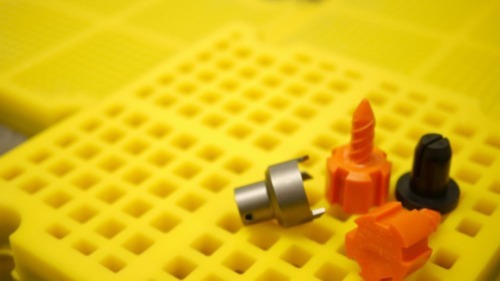

There are several types of screens to choose from, the first is polyurethane. Polyurethane media tends to command the highest price points but offers long wear life. While there’s some debate to be had, polyurethane generally performs best for screens that are ¾” and smaller. It’s a great material for minimizing sliding abrasion – in other words, it works well for wet applications, like rinsing for sand or gravel processing.

The next one we’ll take a look at is rubber. Rubber media is generally a bit more affordable than polyurethane. These aren’t great for sliding abrasion, but they are ideally suited for scalping or for dry applications in high-impact areas. Different levels of durometer (hardness) work best for different applications. 40 durometer rubber, for instance, is more flexible. It’s very good at reducing pegging and blinding in finer separations. 65 durometer rubber is better for systems with heavy feed rates.

Lastly, is wire cloth. The materials listed above (polyurethane and rubber) are typically referred to as synthetic media. Wire cloth is different. It’s typically available at a lower price point than synthetic options. It’s also generally recognized to provide more open area on decks, allowing for increased throughput.

Before you choose your screen media call Mellott 855-554-1606 and have one of our many aggregate professionals assist you. Mellott has your back from start to finish!