It’s that time of year again. For the colder regions, maintenance season is coming to an end and it’s time to fire the plants back up. During maintenance season, usually the main items that are focused on before starting back up are replacing liners, belts, screens, ect. One thing that can easily be overlooked, is preventative maintenance for water contamination in your oils.

Water contamination effects:

• Engines

• Transmissions

• Differentials

• Reducers

• Gear Boxes

• lubrication Systems

• Hydraulic System

In lubricants, water is the second most destructive contaminant behind particles. It causes issues such as rust and the decreased load-carrying capacity (film strength) in oil. It also leads to permanent degradation of the lubricant. Similar to oxidation, hydrolysis is the degradation of the base oil’s molecules as a result of water.. Not only can a base oil degrade to this process, but additives are susceptible as well.

A few preventative measures we can take to prevent and prolong our equipment longevity are:

- Sampling oil on a regular basis. Water can cause a cloudy appearance or can lie on the bottom of an oil sample; however, it cannot always be seen with the naked eye. Sampling regularly can indicate low concentrations of water emulsified in the oil.

- Keep record of and complete manufacturer recommended maintenance intervals.

- Check the sight gauge or level port every day before operations start with the oil at ambient temperature. If you have not added any oil to the system and the oil level has raise, this indicates there is water getting into the system.

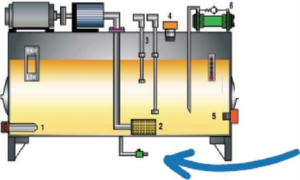

- Periodically, before starting operations, open the drain valve or plug. Drain off the water that has settled in the bottom of the reservoir.

- Use desiccant breathers when available. These breathers not only trap foreign particles but prevent moisture from entering the system. As the moisture in the air passes through the breather, silica gel beads trap the moisture. When the breather is full of moisture the silica changes color, indicating time for breather replacement.

- Housekeeping on breathers should be a daily check, at which time they should be cleaned, inspected, and replaced as needed. It is very common for buildup to occur in and around the breathers. As they draw moisture in, it mixes with dust in the air and causes build up. This restriction changes the volumetric flow needed for proper operation.

- Maintain a correct headspace and do not overfill units. Headspace accommodates for the volumetric changes. lf incorrect, it can result in a vacuum or pressurization condition, prematurely damaging system components.

- When filling from a barrel, be mindful to drain off any sediment and water from the bottom before drawing from the container. Barrels should be stored on their sides and under a shelter. This keeps an oil surface next to the bungs, reducing the likelihood of air circulation and water ingress through natural breathing.

At Mellott, we have an expert team of service technicians all along the eastern United States with the experience and knowledge to assist with all of your equipment service needs from normal maintenance, to full rebuilds. You can trust Mellott to get the job done with professionalism and excellence every time.