When it comes to choosing the right impact crusher for your next project, there are a few important distinctions between these machines to understand. Horizontal Shaft Impactor (HSI) and Vertical Shaft Impactor (VSI) crushers both use impact force to break down materials, but they operate differently and have different benefits depending on the type of material you’re trying to crush. Here, we take a look at how HSI and VSI crushers work and provide some tips on how to choose the right one for your project’s needs.

What Are HSI Crushers?

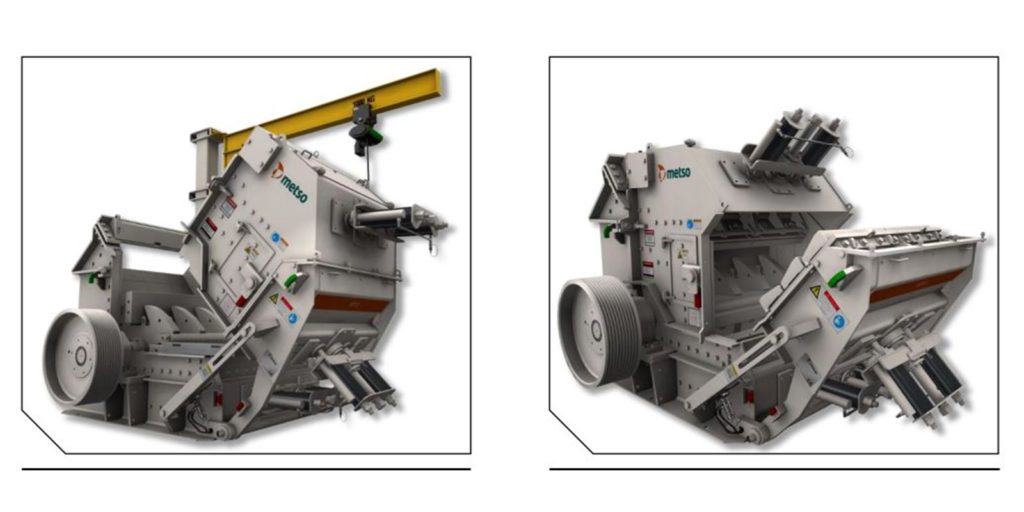

An HSI crusher is one that crushes materials by impacting them against a rotating shaft. The shaft is oriented horizontally, and the material is crushed by the impact of the blows delivered to it by the crusher’s hammers. HSI crushers are most commonly used for crushing concrete and asphalt. They are also well suited for recycling applications, and can be used to crush glass, brick, and other materials.

HSI crushers are commonly used for concrete and asphalt recycling use cases. They offer a number of benefits that make them a better choice than VSI crushers for recycling applications.

Some of those benefits include:

- They can handle a wider range of materials than VSI crushers.

- They produce less fine materials than VSI crushers, making them ideal for recycling applications, where smaller particles are desired.

- They are easier to operate and maintain than VSI crushers.

- They have a longer lifespan than VSI crushers.

What Are VSI Crushers?

A VSI crusher uses a high-speed rotor to drive particles into a crushing chamber. The rotor is mounted on a shaft that spins at speeds up to 3,500 RPM. The particles are thrown against the walls of the chamber and the resulting collision fractures them. VSI crushers are particularly good at crushing hard, abrasive rocks. VSI crushers can also be used to recycle a wide variety of materials, including concrete, asphalt, and glass. They also produce high-quality sand for use in construction and other applications.

VSI crushers have a few advantages over traditional HSI crushers, including:

- Greater production capacity – a VSI crusher can produce up to twice the amount of material as an HSI crusher of the same size.

- More consistent product – a VSI crusher produces more uniform products than an HSI crusher, making it ideal for recycling and tertiary applications.

- Lower wear and tear – VSI crushers have fewer moving parts than HSI crushers, which means less wear and tear and lower maintenance costs.

- Easier operation – VSI crushers are simpler to operate and require less operator training than HSI crushers.

- Lower fuel consumption – VSI crushers use less fuel than HSI crushers, making them more cost-effective in the long run.

How To Choose The Right Crusher For Your Next Project

HSI crushers are more popular because they can be used for a wider range of applications. They are also less expensive than VSI crushers. However, VSI crushers can handle harder materials and produce a finer product. If you need to crush rocks with high compressive strength, then a VSI crusher is the right choice.

There are a few factors you will need to take into account when choosing between an HSI or VSI impact crusher:

Type of Material

The most important factor is the type of material you will be crushing. HSI crushers are typically better suited for softer materials, such as limestone, while VSI crushers are better for harder materials, such as granite.

Size

You will also need to consider the size of the material you will be crushing. If you are dealing with smaller particles, then an HSI crusher may be a better choice, as they typically have a higher throughput rate than a VSI crusher. If you are dealing with larger particles, then a VSI crusher may be a better choice, as they can handle larger rocks.

Budget

An HSI crusher typically costs less than a VSI crusher. However, the throughput rate of an HSI crusher is usually lower than a VSI crusher. So if you are looking for the highest possible production rate, then a VSI crusher may be the best option for you.

Stage of Crushing

The type of crusher you choose for your project depends on the stage of crushing they are planned to be used in. For primary crushing, a jaw crusher or gyrator crusher is typically used. For secondary and tertiary crushing, an impact crusher is most often used. HSI crushers can work in both the primary and secondary stages, while VSI crushers are primarily used towards the end of the crushing process as a tertiary crusher.

Finding The Right Impact Crusher For Your Project’s Needs

When choosing a crusher, it is important to consider the project’s requirements, and how it will be used. Impact crushers are very versatile, and can be tailored to meet specific needs, so it is important to consult with an expert before making a decision. For more information on how to choose the perfect impact crusher for your project’s needs, reach out to the Mellott’s team of experts today at 855.554.1606.